YRTC850 850*1095*124mm Rotary Table Bearing High torque harmonic drive mini gear reducer for industrial robotics

| Designation |

Dimensions (mm) |

Fixing holes |

Threaded extraction hole |

Screw tightening torque

MA

Nm |

| d |

D |

H |

H1 |

H2 |

C |

D1

max. |

J |

J1 |

Inner ring |

Outer ring |

G |

Qty |

| d1 |

d2 |

a |

Qty |

d3 |

Qty |

| YRTC850 |

850 |

1,095 |

124 |

80.5 |

43.5 |

37 |

1,018 |

890 |

1,055 |

18 |

26 |

17 |

58 |

18 |

54 |

M16 |

6 |

284 |

| Designation |

Pitch t |

Basic load ratings |

Rigidity |

Mass m

=kg |

| Quantity X t |

axial |

radial |

bearing position |

rolling element set |

| Including retaining screws and extraction threads |

dyn. Ca

N |

stat.C0a

N |

dyn. Cr

N |

stat. C0r

N |

axial

CaL kN/µm |

radial CrLkN/µm |

Tilting rigidity

CkLkNm/mrad |

axial

CaL kN/µm |

radial

CrL kN/µm |

Tilting rigidity

CkLkNm/mrad |

| YRTC850 |

60 x 6° |

900,000 |

8,500,000 |

460,000 |

1,690,000 |

26.5 |

11.9 |

2,351 |

61.9 |

12 |

6,772 |

253 |

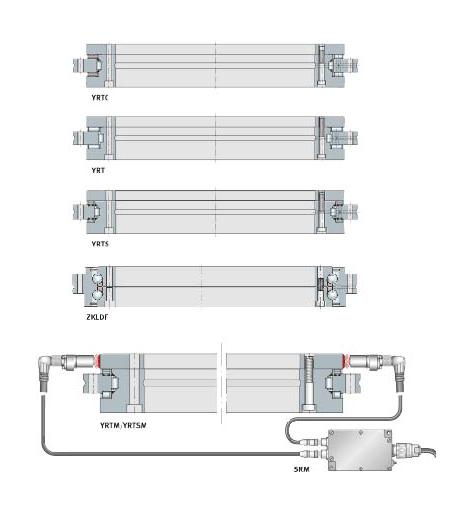

YRT Roatry Table Bearing

Axial/radial bearings

Axial/radial bearings are double direction axial bearings for screw mounting, with a radial guidance bearing. These ready-to-fit,greased units are very rigid, have high load carrying capacity and run with particularly high accuracy. They can support radial forces, axial forces from both directions and tilting moments free from clearance. The bearings are available in several series. For applications with low speeds and small operating durations, such as indexing tables and swivel type milling heads, the most suitable bearings are generally series YRT and YRTC.

For the bearing arrangements of direct drive axes, there is the series YRTS. Due to their high limiting speeds and very low, uniform frictional torque across the whole speed range, these bearings are particularly suitable for combination with torque motors. For higher accuracy requirements, these bearings are also available with restricted axial and radial runout accuracy.

Axial angular contact ball bearings

Axial angular contact ball bearings ZKLDF are low-friction, ready-to-fit, pregreased bearing units with high accuracy for very high speeds, high axial and radial loads and high demands on

tilting rigidity.Axial angular contact ball bearings are particularly suitablefor precision applications involving combined loads. Their preferred areas of use are bearing arrangements in rotary tables with a main

spindle function, for example in combined milling and turning, as well as in milling, grinding and honing heads and in measurement and testing equipment.

Axial/radial bearings with angular measuring system

Axial/radial bearings with angular measuring system YRTM and YRTSM correspond in mechanical terms to series YRT and YRTS, but are additionally fitted with an angular measuring system. The measuring system can measure angles to an accuracy of a few angular seconds by non-contact, magneto-resistive means.

Further information on axial/radial bearings with absolute value angular measuring systems YRTMA and YRTSMA can be found in special publication SSD 30.

Features

Axial radial bearings YRT, YRTC and YRTS and axial angular contact ball bearings ZKLDF are ready-to-fit high precision bearings for high precision applications with combined loads. They can support radial loads, axial loads from both sides and tilting moments without clearance and are particularly suitable for bearing arrangements with high requirements for running accuracy.

Due to the fixing holes in the bearing rings, the units are very easy to fit.

The bearings are radially and axially preloaded after fitting.

The mounting dimensions of all series are identical.

Axial/radial bearings YRT in the size range of d = 580 mm to d = 1 030 mm have been replaced by YRTC.

Compared with the predecessor product YRT, these bearings have higher rigidity, a higher limiting speed and lower bearing friction.

With angular measuring system

Axial/radial bearings are also available with an absolute value angular measuring system or have systems with pitch-coded reference marks. The measuring systems can measure angles to an accuracy of a few angular seconds by non-contact means.

Areas of application For standard applications with low speeds and small operatingdurations, such as indexing tables and swivel type milling heads, the most suitable bearings are generally series YRT and YRTC.

For the bearing arrangements of direct drive axes, there is the series YRTS. Due to their high limiting speeds and very low, uniform frictional torque across the whole speed range, these bearings are

particularly suitable for combination with torque motors.

For higher accuracy requirements, these bearings are also available with restricted axial and radial runout accuracy.

Axial angular contact ball bearings ZKLDF are particularly suitable for high speed applications with long operating duration.

They are characterised by high tilting rigidity, low friction and low lubricant consumption.

Axial/radial bearings

Axial/radial bearings YRT, YRTC and YRTS have an axial and a radial component.

The axial component comprises an axial needle roller or cylindrical roller and cage assembly, an outer ring, L-section ring and shaft locating washer and is axially preloaded after fitting. The radial

component is a full complement cylindrical roller set in YRT and a cage-guided, preloaded cylindrical roller set in YRTC and YRTS.

The outer ring, L-section ring and shaft locating washer have fixing holes. The unit is located by means of retaining screws for transport and safe handling.

Sealing

Axial/radial bearings are supplied without seals.

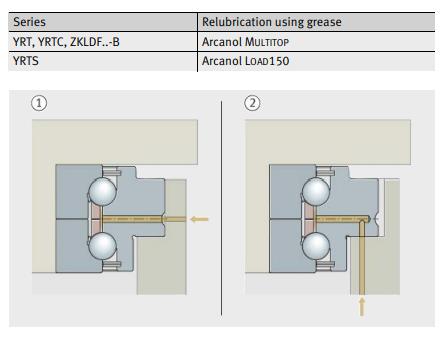

Lubrication

The initial greasing of YRTS corresponds to the grease Arcanol LOAD150 and, in the case of YRT and YRTC, to the grease Arcanol MULTITOP. The bearings can be lubricated via the outer ring and

L-section ring.

Axial angular contact ball bearings

Axial angular contact ball bearings ZKLDF comprise a single-piece outer ring, a two-piece inner ring and two ball and cage assemblies with a contact angle of 60°. The outer ring and inner ring have fixing holes for screw mounting of the bearing on the adjacent construction.

The unit is located by means of retaining screws for transport and safe handling.

Sealing

Axial angular contact ball bearings have sealing shields on both sides.

Lubrication

The initial greasing of current axial angular contact ball bearings ZKLDF (Generation B) corresponds to the grease Arcanol MULTITOP. The bearings can be relubricated via the outer ring.

Operating temperature

Axial/radial bearings and axial angular contact ball bearings are suitable for operating temperatures from –30 °C to +120 °C.

Available designs

Design andsafety guidelines

General safety guidelines The general safety guidelines must be observed. Further information relating to safety of control circuits: see Axial/radial bearings with angular measuring system.

Basic rating life

The load carrying capacity and life must be checked for the radial andaxial bearing component.

Please contact us in relation to checking of the basic rating life.

The speed, load and operating duration must be given.

Limiting speeds

In bearing selection, the following guidelines and the limiting speeds must be observed, see dimension tables.

If the environmental conditions differ from the specifications in relation to adjacent construction tolerances, lubrication, ambient temperature, heat dissipation or from the normal operating conditions for machine tools, the stated limiting speeds must be checked. Please contact us.

Axial/radial bearing YRT

Axial/radial bearings YRT are designed, by means of the full complement radial roller bearing component for high rigidity, for rapid positioning and operating at low speed. Low speeds are normally required for multiple-axis simultaneous machining.

The limit value nG stated in the dimension tables relates to the maximum swivel speed and a maximum speed applied for a short period.

Axial radial bearings YRTC, YRTS and ZKLDF axial angular contact ball bearings

The limiting speeds nG stated for these bearing series were determined on test rigs.

During the test, the following conditions apply:

■ grease distribution cycle according to the defined data,

■ maximum increase in bearing temperature of 40 K in the areaof the raceway

■ operating duration ED = 100%, which means continuous operation at the limiting speed nG

■ bearing fully screw mounted on solid fixtures

■ no external load, only preload and mass of the fixtures.

Temperature distribution in the rotary axis system

Rotary axes with a main spindle function, such as those used for combined milling and turning and with direct drive by a torque motor, are systems with complex thermal characteristics.

The temperature distribution in the rotary axis system must be considered in greater detail during the design process:

■ Asymmetrical rotary axis housings can undergo asymmetrical deformation due to heating.

■ In turn, out-of-round bearing seats lead to additional bearing load, reduced life and a negative influence on running behaviour and running accuracy.

■ Temperature management of the rotary axis in the form of targeted cooling and heating is generally necessary for high performance rotary axes.

Where there is non-uniform temperature distribution between the inner and outer ring, rotary axis bearings with ball contact (ZKLDF) show more tolerant behaviour than rotary axis bearings with line contact (such as axial/radial cylindrical roller bearings or crossed roller bearings).

The stated bearing characteristics only apply if the bearing preload remains unchanged. The bearing preload can be altered by mechanical stresses, such as those which can be caused by temperature differences or adjacent machine elements (such as force-locking clamping connections for example).

Design regulations

Proven design regulations based on practical experiences,

■ The contact face between the stator of the torque motor and the rotary table housing should be as small as possible, in order to minimise the flow of heat between stator and rotary table housing.

■ Where possible, do not connect the casing of the stator cooling system to the rotary table housing.

■ In preference, flange mount the rotor of the torque motor on the rotary table plate rather than on the bearing, to keep the flow of heat through the bearing to a minimum.

■ The distance between the motor and the bearing should be as large as possible. A large distance reduces the transfer of heat from the rotor to the bearing. The stresses occurring between the components as a result of varying thermal expansion are reduced by the increased elasticity of the system.

■ The rotary table plate bearing must be centered with sufficient rigidity to allow the overall system to attain a high level of rigidity.

The risk of deformation to the bearing seat due to the increase in the temperature of the rotor is also reduced.

■ Use torque motors which are suitable for the requirements only, with low loss of power and a high motor constant. We recommend using IDAM torque motors.

Regulated cooling of the stationary and rotating components may be required in order to limit the temperature variations between the bearing inner and outer ring.

Bearing preload

Once the bearings have been fitted and fully screw mounted, they are radially and axially clearance-free and preloaded.

Temperature differences

Temperature differences between the shaft and housing influence the radial bearing preload and thus the operating behaviour and operating life of the bearing arrangement.

If the shaft temperature is higher than the housing temperature, the radial preload will increase proportionally, so there will be an increase in the rolling element load, bearing friction and bearing

temperature, while the operating life will be reduced.

If the shaft temperature is lower than the housing temperature,the radial preload will decrease proportionally, so the rigidity will decrease to bearing clearance. There will be an increase in wear, the operating life will be reduced and noise due to slippage may occur.

Frictional torque

The bearing frictional torque MR is influenced primarily by the viscosity and quantity of the lubricant and the bearing preload:

■ The lubricant viscosity is dependent on the lubricant grade and operating temperature.

■ When relubrication is carried out, the lubricant quantity is increased for a short time until the grease is distributed and the excess quantity has left the bearing.

■ During initial operation and after relubrication, bearing friction is increased until the lubricant has been distributed within the bearing.

■ The bearing preload is dependent on the mounting fits, the geometrical accuracy of the adjacent parts, the temperature difference between the inner and outer ring, the screw tightening torque and mounting situation (bearing inner ring axially supported on one or both sides).

In the case of series YRT, the bearing frictional torque is heavily influenced by the tightening torque of the inner ring fixing screws.

As a result, the preload in the axial bearing parts can be increased by using screws of grade 12.9 and the corresponding tightening torque if required.

If a lower frictional torque is to be achieved, this can, for example, be realised by reducing the screw tightening torque. As the selflocking function of the screw connection which secures against loosening is also reduced as a result, the screws must be secured using suitable thread lockers.

For applications which are sensitive to frictional torque, we recommend using series ZKLDF or YRTS.

Relubrication and initial operation

The speed capability, friction, rating life, functional capability and the durations of relubrication intervals are essentially influenced by the grease used, see table. Axial/radial bearings YRT, YRTC and YRTS can be relubricated via a lubrication groove in the L-section ring and the outer ring. Axial angular contact ball bearings ZKLDF can be relubricated via a lubrication groove in the outer ring. The bearing series YRTC, YRTS and ZKLDF have an additional lubrication connector in the screw mounting face of the outer ring. This allows reliable feed of lubricant even where there is a large fit clearance in the bearing seat or the outer ring is free. For calculation of the relubrication quantities and intervals based on a stated load spectrum (speed, load, operating duration) and the environmental conditions, please contact us.

1.Relubrication via the lubrication groove in the outer ring

2.Relubrication via the outer ring screw mounting face

Initial operation

Rolling bearings may exhibit increased frictional torque during initial operation, which can lead to overheating where there is immediate operation at high speeds.

Overlubrication

The bearings may be damaged by overheating as a result of increased frictional torque when operating at high speeds if they have been accidentally overlubricated.

Design of adjacent construction

YRT, YRTS and ZKLDF have almost the same mounting dimensions.

Geometrical defects in the screw mounting surfaces and fits will influence the running accuracy, preload and running characteristics of the bearing arrangement. The accuracy of the adjacent surfaces must therefore be matched to the overall accuracy requirement of the subassembly. The tolerances of the adjacent surfaces must lie

within the running tolerance of the bearing.

The adjacent construction should be produced in accordance with Figure 16 and the tolerances must be in accordance with the tables starting . Any deviations will influence the bearing frictional torque, running accuracy and running characteristics.

Fits

The selection of fits leads to transition fits, i.e. depending on the actual dimensional position of the bearing diameter and mounting dimensions, clearance fits or interference fits can arise.

The fit influences, for example, the running accuracy of the bearing and its dynamic characteristics.

An excessively tight fit will increase the radial bearing preload.

As a result:

■ there is an increase in bearing friction and heat generation in the bearing as well as the load on the raceway system and wear

■ there will be a decrease in the achievable speed and the bearing operating life.

For easier matching of the adjacent construction to the actual bearing dimensions, each bearing of series YRT and YRTS is supplied with a measurement record (this is available by agreement for other series).

Axial and radial runout accuracy of the bearing arrangement

The axial and radial runout accuracy is influenced by:

■ the running accuracy of the bearing.

■ the geometrical accuracy of the adjacent surfaces.

■ the fit between the rotating bearing ring and adjacent component.

Installation Instructions

1. Bearing installation diagram

1.1 Design & Installation Structure with the requirements shown in Figure 1 Retaining screws secure the bearing components during transport. For installing the bearing easier, the screws should be loosened before fitting, and secured again or replaced by positioning screws after fitting.

1.2 The L-section ring can be fitted with unsupported or supported ring.

a) Without supported ring, the bearing type is YRT.

b) With supported ring, the bearing type is YRT…VSP,And the whole surface of L-section should be supported.

1.3 Mounting forces must only be applied to the bearing ring to be fitted, never through the rolling elements.Tighten the fixing screws in crosswise using a torque wrench (shown in figure 2).

1.4 Don’t separate or interchanged bearing components during fitting and dismantling.

1.5 Starting friction torque can be 3 to 3.5 times as high as the value of friction torque in the dimension tables.

2. Bearing Lubrication Maintenance

YRT Rotary Table bearing use German high quality grease for lubrication, standard oil filling

holes are made on the bearing, lubrication maintenance points are as follows:

2.1 Grease:LUBCON Turmogrease Li 802 EP (Made in German)

2.2 Grease maintenance cycletime: 3-5 months;

2.3 Check the situation of bearing grease regularly, ensure an clean environment to prevent

contaminants from entering the bearing;

2.4 Fill the grease by oil guns or other tools through the oil holes location as shown below:

Machining tolerances for shafts

| Bearings |

shaft diameter (mm) |

roundness(○) |

perpendicularity(⊥) |

parallelism(∥) |

roughness Ra |

| Nominal dimension |

upper |

lower |

t1(µm) |

t3(µm) |

t4(µm) |

Ra(µm) |

| YRT50 |

50 |

0 |

-0.011 |

4 |

3 |

3 |

0.4 |

| YRT80 |

80 |

0 |

-0.013 |

5 |

3 |

3 |

0.4 |

| YRT100 |

100 |

0 |

-0.015 |

6 |

4 |

4 |

0.4 |

| YRT120 |

120 |

0 |

-0.015 |

6 |

4 |

4 |

0.4 |

| YRT150 |

150 |

0 |

-0.018 |

8 |

5 |

5 |

0.8 |

| YRT180 |

180 |

0 |

-0.018 |

8 |

5 |

5 |

0.8 |

| YRT200 |

200 |

0 |

-0.02 |

10 |

7 |

7 |

0.8 |

| YRT260 |

260 |

0 |

-0.023 |

12 |

8 |

8 |

0.8 |

| YRT325 |

325 |

0 |

-0.025 |

13 |

9 |

9 |

0.8 |

| YRT395 |

395 |

0 |

-0.025 |

13 |

9 |

9 |

0.8 |

| YRT460 |

460 |

0 |

-0.027 |

15 |

10 |

10 |

0.8 |

| YRT580 |

580 |

0 |

-0.028 |

16 |

11 |

11 |

1.6 |

| YRT650 |

650 |

0 |

-0.032 |

18 |

12 |

12 |

1.6 |

| YRT850 |

850 |

0 |

-0.036 |

20 |

14 |

14 |

1.6 |

| YRT950 |

950 |

0 |

-0.036 |

20 |

14 |

14 |

1.6 |

| YRT1030 |

1030 |

0 |

-0.045 |

25 |

16 |

16 |

1.6 |

| YRT1200 |

1200 |

0 |

-0.054 |

18 |

18 |

18 |

1.6 |

Machining tolerances for housings

| Bearings |

(mm)housing diameter |

roundness(○) |

perpendicularity(⊥) |

parallelism(∥) |

roughness Ra |

| Nominal dimension |

upper |

lower |

t1(µm) |

t3(µm) |

t4(µm) |

Ra(µm) |

| YRT50 |

126 |

+0.018 |

-0.007 |

8 |

5 |

5 |

0.8 |

| YRT80 |

146 |

+0.018 |

-0.007 |

8 |

5 |

5 |

0.8 |

| YRT100 |

185 |

+0.022 |

-0.007 |

10 |

7 |

7 |

0.8 |

| YRT120 |

210 |

+0.022 |

-0.007 |

10 |

7 |

7 |

0.8 |

| YRT150 |

240 |

+0.022 |

-0.007 |

10 |

7 |

7 |

0.8 |

| YRT180 |

280 |

+0.025 |

-0.007 |

12 |

8 |

8 |

0.8 |

| YRT200 |

300 |

+0.025 |

-0.007 |

12 |

8 |

8 |

0.8 |

| YRT260 |

385 |

+0.029 |

-0.007 |

13 |

9 |

9 |

0.8 |

| YRT325 |

450 |

+0.033 |

-0.007 |

15 |

10 |

10 |

0.8 |

| YRT395 |

525 |

+0.034 |

-0.01 |

16 |

11 |

11 |

1.6 |

| YRT460 |

600 |

+0.034 |

-0.01 |

16 |

11 |

11 |

1.6 |

| YRT580 |

750 |

+0.038 |

-0.012 |

18 |

12 |

12 |

1.6 |

| YRT650 |

870 |

+0.044 |

-0.012 |

20 |

14 |

14 |

1.6 |

| YRT850 |

1095 |

+0.052 |

-0.014 |

24 |

16 |

16 |

1.6 |

| YRT950 |

1200 |

+0.052 |

-0.014 |

24 |

16 |

16 |

1.6 |

| YRT1030 |

1300 |

+0.060 |

-0.016 |

27 |

18 |

18 |

1.6 |

| YRT1200 |

1490 |

+0.068 |

-0.02 |

20 |

20 |

18 |

1.6 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!