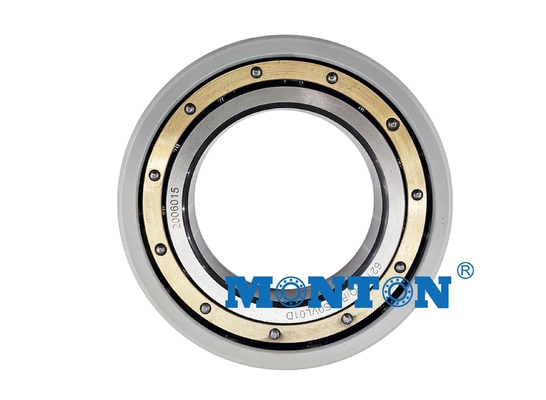

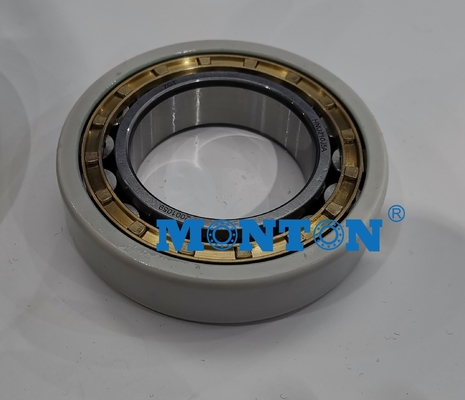

NU326ECM/C3VL2071 130*280*58mm Insulated Insocoat bearings for Electric motors

| Bearing |

Dimension |

Basic Dynamic Load Rating |

Fatigue Limit Load |

rated speed |

| dynamic |

static |

Reference speed |

Limiting speed |

| d[mm] |

D[mm] |

B[mm] |

C[kN] |

C0[kN] |

Pu[kN] |

[r/min] |

[r/min] |

| NU326ECM/C3VL2071 |

130 |

280 |

58 |

720 |

750 |

81.5 |

2400 |

3000 |

Electric motors, generators and associated equipment are at risk when an electric current passes through their bearings. This can damage the contact surfaces of rolling elements and raceways in the bearings (electrical erosion) and rapidly degrade the grease. An additional risk in electric motors and generators comes from high frequency currents caused by the inherent stray capacitance.

The risk of damage increases where the application uses a frequency converter.

Insulated Insocoat bearings are designed to prevent electric current from passing through the bearing

have the external surfaces of either their inner or outer ring coated with an insulating aluminium oxide layer, by applying a sophisticated plasma-spray process for an outstanding quality finish

are a very cost-effective solution compared with other insulation methods.

Electrical pitting often occurs in the use of rolling bearings in high power electromotor, wind turbine generator and rail vehicles motor systems and cause sparks that damage the rolling contact surface, ultimately lead to bearing failure.

Electric insulated bearings therefore have been created and take the place of non-insulated bearings. we applies advanced surface modification process overlay a ceramic coating on the bearing ring, to insulate the electrical current flow into bearing substrate, so the electrical pitting is prevented and bearing's service life is extended.

It is significantly more cost-effective to provide for the use of electrically insulated bearings at the planning stage. As a result, customer benefit is increased through reduced maintenance costs and higher machine availability.

SAT series are the electrically insolated bearing products developed and marketed by us The insulation has a guaranteed breakdown resistance of at least 1000V AC or DC. We can also develop tailored modes for customer on types and precision levels, as well as higher electrical insulation.

Bearing features

Protection against electrical erosion

With insulating properties integrated into the bearing, INSOCOAT bearings can improve reliability and increase machine uptime by virtually eliminating the problem of electrical erosion.

High electrical resistance

The aluminium oxide coating provides a minimum electrical resistance of 200 MΩ and can withstand voltages up to 3 000 V DC.

Consistent electrical performance

Plasma-spray coatings are normally hygroscopic and, therefore, vulnerable to penetration caused by condensation. To protect against this effect, INSOCOAT bearings are treated with a unique sealant.

Application of Insulated Bearings in Electric motors

1. Causes and harm of motor shaft voltage and bearing current formation

In the operation of the motor, any imbalance in the phase currents in or around the rotor’s magnetic circuit can produce a rotating system flux linkage.

When the shaft rotates, these flux chains can generate a potential difference across the shaft. This potential difference is called the shaft voltage. The shaft voltage can excite a circulating current through a loop formed by the two ends of the bearing in the shaft and the casing (closed circuit), which is called the shaft current.

In addition, the rotor core has more remanence, For a wound rotor motor, shaft voltage and shaft current are generated if two or more windings are short-circuited to the rotor core or the shaft. the bearing current is related to the structure of the motor, the power of the motor, the magnitude of the drive voltage, the rise time of the pulse, the length of the cable, etc. The larger the power of the motor, the higher the driving voltage, the steeper the rising edge of the driving voltage, and the shorter the cable, the larger the bearing current.

2. How to block shaft current – use electrically insulated bearings

In order to avoid damage to the bearing caused by the shaft current, effective measures should be taken to isolate the shaft current. For large motors with independent bearing housings at both ends, spacers made of insulating material can be placed between the bearing housing and the metal base. For a motor in which an ordinary bearing and a casing are integrated, an Electrically insulated bearing is generally used at one end thereof (often arranged at the non-spindle end).

For high requirements, insulated bearings are installed at both ends. The insulating bearing used is generally a method of attaching (generally coating) an insulating layer to the outer ring. In some cases, the inner and outer rings are also provided with an insulating layer.

Electrically insulated bearings avoid damage caused by electrical corrosion, so they are more reliable in operation than in conventional bearings. And compared to other insulation methods, such as shaft or housing insulation, etc. More cost effective and reliable. Insulated bearings have the same dimensions and basic technical features as non-insulated bearings Suitable for motors, generators, especially variable frequency motors.

CoatMaster (China Bearing manufacturer), As the exprienced Electrically Insulated Bearing manufacturer of China, Not only produce insulated deep groove ball bearing, insulated cylindrical roller bearing, insulated tapered roller bearing, insulated angular contact ball bearing and the other type of insulated bearing, but also supply complete and expert solution for electric motor and the other applications where need insulated bearing. if you have problem make you distracted about the insulated bearing, just contact with our bearing technical team.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!