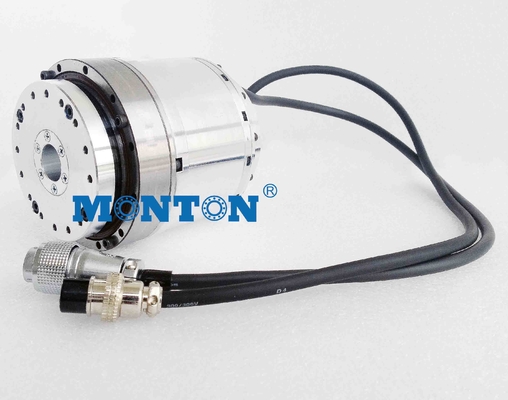

KAH-25CL3NE Hollow Shaft Harmonic Drive CNC machine reducer high precision

| KAH-25 encoder Specification parameter |

| Series |

KAH-25 |

| Model KAH-25 |

25A |

25B |

25C |

25D |

25E |

| Deceleration ratio |

1:51 |

1:81 |

1:101 |

1:121 |

1:161 |

| Maximum torque starting &stopping(N·M) |

497 |

641 |

702 |

762 |

800 |

| Instantaneous maximum torque(N·M) |

242 |

351 |

460 |

557 |

557 |

| AC voltage 220VAC |

Maximum speed |

RPM |

76.5 |

48.1 |

38.6 |

32.2 |

24.2 |

| Rated speed |

RPM |

43.1 |

27.2 |

21.8 |

18.2 |

13.7 |

| Maximum current |

Arms |

22.79 |

18.51 |

16.26 |

14.73 |

11.62 |

| Rated current |

Arms |

8.67 |

7.92 |

8.32 |

8.41 |

6.32 |

| Torque constant |

N·M/Arms |

27.91 |

44.32 |

55.26 |

66.23 |

88.09 |

| Motor phase resistance |

Ohms |

1.024 |

| Motor phase inductance |

mH |

3.026 |

| Motor Back EMF |

Vrms/kRPM |

50.87 |

| AC voltage 1100VAC |

Maximum speed |

RPM |

52.9 |

33.3 |

26.7 |

22.3 |

16.8 |

| Rated speed |

RPM |

35.3 |

22.2 |

17.8 |

14.9 |

11.2 |

| Maximum current |

Arms |

35.85 |

29.12 |

25.58 |

23.17 |

18.29 |

| Rated current |

Arms |

14.55 |

13.29 |

13.97 |

14.11 |

10.61 |

| Torque constant |

N·M/Arms |

16.63 |

26.41 |

32.93 |

9.47 |

52.5 |

| Motor phase resistance |

Ohms |

0.53 |

| Motor phase inductance |

mH |

1.207 |

| Motor Back EMF |

Vrms/kRPM |

44.96 |

| AC voltage 480VAC |

Maximum speed |

RPM |

35.30 |

22.20 |

17.80 |

14.90 |

11.20 |

| Rated speed |

RPM |

29.40 |

18.50 |

14.90 |

12.40 |

9.30 |

| Maximum current |

Arms |

72.66 |

75.06 |

51.81 |

46.98 |

37.05 |

| Rated current |

Arms |

35.38 |

41.10 |

33.95 |

34.34 |

25.82 |

| Torque constant |

N·M/Arms |

6.84 |

8.54 |

13.55 |

16.22 |

21.59 |

| Motor phase resistance |

Ohms |

0.139 |

| Motor phase inductance |

mH |

0.207 |

| Motor Back EMF |

Vrms/kRPM |

17.48 |

| Absolute Encoder |

Encoder Type |

Hollow absolute multiturn encoders ,Single-loop 19,22or24, multiturn16 |

| Encoder resolution Motor(1time)rotation |

219(524,288),222(4,194.304)or224(16777216) |

| Motor multiple rotation counter |

215(65.536) |

| Incremental |

Encoder resolution |

Hollow incremental encoder,40000impulse/rpm(4 time signal) |

| encoder |

Output shaft resolution |

pulse/rev |

2040000 |

3240000 |

4040000 |

4840000 |

6440000 |

| uniderection positioning accuracy |

Arc Sec |

60 |

40 |

40 |

40 |

40 |

| Bidirectional positioning accuracy |

Arc Min |

2 |

1.5 |

1 |

1 |

1 |

| Overturning stiffness |

×104 N·m /rad |

120.5 |

157.4 |

| Torsional stiffness |

×104 N·m /rad |

14 |

18.6 |

| Moment of inertia |

without Brake |

Kg*m2 |

3.91 |

9.86 |

15.36 |

22.68 |

39.86 |

| with Brake |

Kg*m2 |

4.62 |

12.03 |

18.39 |

26.35 |

47.50 |

| Weight |

without Brake |

Kg |

9.1 |

| with Brake |

Kg |

9.7 |

| Motor Grade |

16 |

| Motor insulation |

Heat resistance grade :F(155℃) |

| Insulation resistance:above200MΩ(DC500V) |

| Dielectric Strength:AC1500V/1min |

| Protection grade |

Fully closed self cooling type(IP65/IP67 degree) |

Main Features

1. KAH series hollow shaft rotary actuator provides large-torque and high-precision rotary actuation. With integrated design, processing and assembly technique, it is provided with high precision harmonic drive reducer, frame-less torque motor, hollow shaft high resolution absolute encoder, brake and intelligent sensor.

2. It provides high torque output and high torque density, for example, the torque of KAH-40 rotary actuator can reach 800N·m.

The positioning precision of rotary actuator is within 30 Arc sec.

3.An internal through-hole is set to facilitate threading of wires, gas pipe and laser beams, which simplify the system structure.

4.Dozens of product models are provided to meet diversified needs, and the products with 220 VAC, 110VAC and 48 VAC voltages are available.

5.High protection grade (IP67) makes the product applicable to severe working environment.

6. It can be used by matching with KDE series EtherCAT Bus Servo Drivers to realize ultra-low vibration control and reliable stable operation, through which offers an integrated drive control solution to customers.

Models of KAH series Hollow Shaft Rotary Actuators can be offered as below:

KAH-14, KAH-17, KAH-20, KAH-25, KAH-32, KAH-40.

Application field

•Industrial robot

•Humanoid robot

•Metal machine tools

•Processing machinery of printing

•Semiconductor manufacturing equipment

•Aerospace equipment

•Numerically-controlled machine tool

•Medical apparatus and instruments

Principle of harmonic drive

Harmonic gear transmission principle

The harmonic gear drive invented by an American inventor, C· W· Musser,. usser in 1955,It is a new type of transmission,which uses the elastic defor mation of flexible components for motion or power transmission. It breaks through the mode of using the rigid component to realize mechanical drive, but with a flexible component instead,thus obtaining a series of special functions that other transmission cannot reach. Its name comes from the deformation process of the intermediate flexible component, which is a symmetrical harmonic. Except that the former Soviet .Union called this kind of transmission"Wave Transmission" or "Flexible Gear Drive", other countries like America, England, Ger many, and Japan all called it "Harmonic Drive’’.

Deceleration principle

The principle of har monic gear transmission deceleration is to use the relative motion of the flexible gear, rigid gear and wave generator (mainly the controllable elastic defor mation of the flexible gear), to realize the motion and power transmission. The elliptical cam in the wave generator rotates in the flexible gear, causing the flexible gear to defor m.When the flexible gear teeth and the rigid gear teeth at both ends of the long shaft of the elliptical cam in the wave generator enter the engagement, the flexible gear teeth at both ends of the shor t shaft are disengaged from the rigid gear teeth. For the teeth between the long shaft and the shor t shaft of the wave generator, the half meshing state that is gradually entering into the meshing along the dif ferent par ts of the circumference of the flexible gear and the rigid gear, is called meshing and the half meshing state that is gradually disengaging is called engaging-out.The continuous rotation of elliptical cam in wave generator makes the flexible gear defor m constantly, w hich causes the teeth at the flexible gear and rigid gear to shift between the states of engaging-in, meshing, engaging-out and disengagement,thus realizing motion transmission from active wave generator to the flexible gear.

The composition of the harmonic gear assembly

Rigid gear : A rigid inter nal gear, usually 2 teeth more than a flexible gear,usually fixed onto the case;

Flexible gear : Thin-cup metal elastic par t with gears on the outer ring of the opening par t.It deforms with the rotation of the wave generator and is usually connected to the output shaft;

Wave generator : Consisting of an elliptical cam and a flexible bearing, usually connected with an input shaft. The inner ring of the flexible bearing is fixed on the cam, and the outer ring can be elastically shaped into an ellipse through the ball bearing.

Application field

•Industrial robot

•Humanoid robot

•Metal machine tools

•Processing machinery of printing

•Semiconductor manufacturing equipment

•Aerospace equipment

•Numerically-controlled machine tool

•Medical apparatus and instruments

Please contact with us for more infotmation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!